close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

Product Description

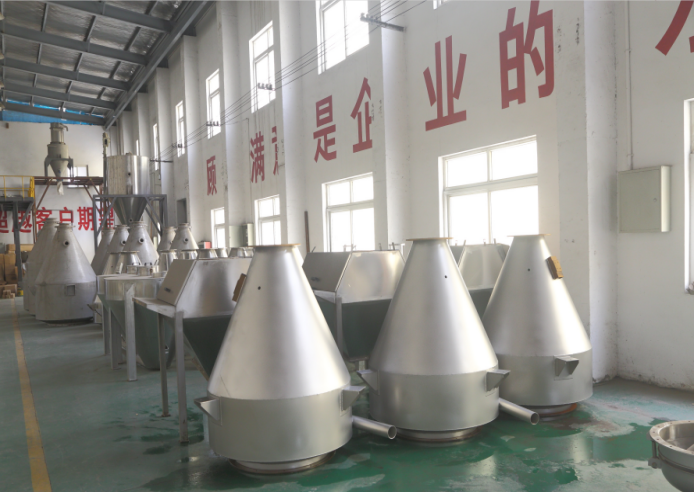

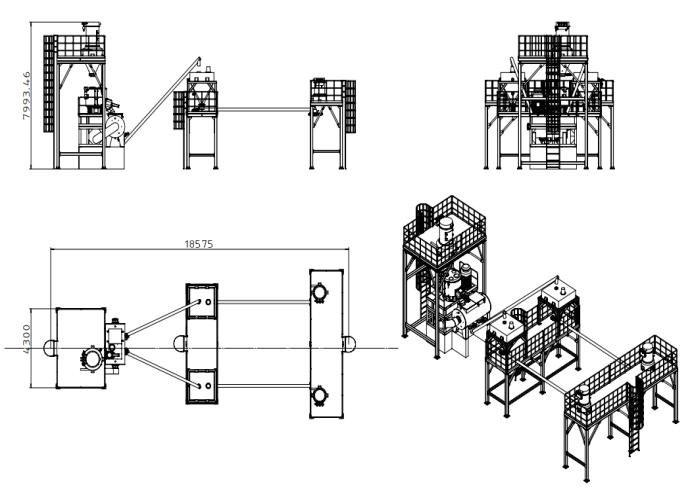

Starsplas manufactures automatic mixing systems designed specifically for mixing workshops in the PVC or WPC plastics industry. This closed system is used for automatic metering, feeding, mixing and feeding of various powder, particle and liquid extrusions. It saves labor and prevents employees from coming into direct contact with the powder.

1. Automatic feeding system - unattended

SPC PVC Automatic Mixing solutions are designed specifically for mixing workshops in the PVC or WPC plastics industry. This closed system is used for automatic metering, feeding, mixing and feeding of various powders, particles and liquids. It results in labor - savings and prevents direct contact with the powder.

2. Central Dust Collection System - Dust free

PVC, WPC plastic industry mixing workshop dust more, worker mobility. When the central feeding system is adopted, we choose to connect the dust collector with the dust producing port, so that this part can be collected and recycled. Dust-free workshop is not only the modern industrial standard, but also can save a lot of materials and labor.

3. Central control system -- intelligent

The intelligent control system is to avoid mistakes and losses caused by manual operation, such as feeding formula error leading to batch unqualified, secondary processing waste. Lack of automatic feeding function can lead to under-filling, which is damaging to screw and extruder. The key is the lack of an automated system for calculating materials based on production.

| component | power | ||||||

| Heating/cooling mixer combination | 245KW | ||||||

| PVC&CACO3 automatic dosing weighing system | 18.5KW | ||||||

| Automatic additive weighing system | 7.8KW | ||||||

| Additive dust removal system | 1.5KW | ||||||

Widely used in chemical, battery raw materials, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, new refractories, electronics, plastics, ceramics, fertilizer, metallurgy, mining, dry mortar, EPS, special building materials industry, such as powder, solid powder liquid mixture.

Q&A

1. How to maintain the mixer?

①. Must be carried out according to the operation procedures of the equipment, which is a good maintenance of the equipment.

②. Pay attention to the equipment after normal start before adding mixture, adding should be in the required order slowly.

③. Prepare the rubber ring, rubber ring, V belt and rolling bearing for the sealing ring, coupling. The working parts of these parts are prone to failure. If necessary, they should be replaced in time, periodically (generally in the first quarter) to check whether the fasteners are loose, check the tightness of the installation of the V belt, and all parts of the equipment should be cleaned and cleaned.

Contact information

WhatsApp:+86 19962650268

TEL:+86 19962650268

Wechat:+86 19962650268

Mail:eve@starsplas.com

Product display drawing