close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Product Description

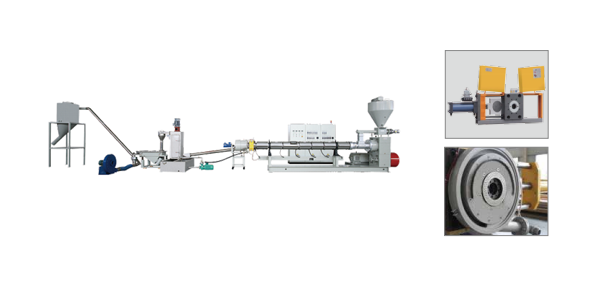

| Advanced Screw Design | 01)The unique screw configuration is tailored to optimize the melting, mixing, and pelletizing of different polymers, ensuring a high-quality output with excellent homogeneity. |

| High-Torque Gearbox | 02)The extruder is equipped with a high-torque gearbox that ensures stable operation with minimal noise, even under heavy load conditions. This feature enhances the machine's durability and efficiency. |

| Durable and Efficient | 03)The screw and barrel are treated with specialized surface coatings, offering exceptional wear resistance and improved mixing efficiency. This extends the lifespan of the components while maximizing output. |

| Vacuum or Natural Venting | 04)The extruder includes vacuum venting or natural venting options, which help remove moisture and gases during the extrusion process. This ensures that the pellets are dry, compact, and have superior quality. |

| High Output | 05)Designed to achieve a high throughput, the STarsplas extruder ensures efficient production of uniform plastic pellets, contributing to reduced production costs and improved recycling capabilities. |

| model | Screw diameter (mm) | aspect ratio | Screw speed (rpm) | Main motor power (kw) | Reference production capacity (kg/h) |

| JWL45 | 45 | 25-35 | 20-100 | 11-15 | 30-50 |

| JWL65 | 65 | 25-35 | 20-100 | 30-37 | 60-120 |

| JWL90 | 90 | 25-35 | 20-90 | 45-55 | 180-200 |

| JWL120 | 120 | 25-35 | 20-75 | 75-110 | 250-350 |

Energy Efficiency: The system’s low noise and smooth operation, thanks to the high-torque gearbox and advanced design, help reduce energy consumption and improve overall operational efficiency.

High-Quality Pellets: The combination of advanced screw design and effective venting ensures the production of dense, high-quality pellets with minimal defects.

Versatility: Capable of processing a wide range of plastics, the STarsplas Series is highly versatile and can be adapted to meet specific material requirements in recycling plants.

User-Friendly: Easy to operate and maintain, the extruder’s centralized control system simplifies the management of production parameters, reducing downtime and increasing productivity.

The STarsplas Series Single-Screw Pelletizing Extruder offers an efficient and cost-effective solution for the plastic recycling industry. Whether processing PP, PE, PS, ABS, or PC, it ensures consistent, high-quality pellets that meet the demanding standards of modern recycling operations.